We produce these machines for 60 years.

In addition, we install the Komple Gin Facility. It comes to the conduit in the gin room through the cotton aspirator and the pipes coming from the warehouse. After passing through the first cleaning machine, automatic dispenser on top of the gin is delivered with the help of cotton spirals. The cores are separated in the ginning machine, which has two rows facing each other. It is sent to the core hall by means of the bottom coil. The clean cotton walking bag coming out of the front of the cabin is poured into the final cleaning machine. The cotton coming out of the cabin is conveyed to the cotton bale press with the help of tape. Balls of 200-220 Kg come here. Our machine is 100 Kg per hour. Core cotton.

The facilities we have set up in various cotton regions of the world are still working and we are helping to buy new machines to extend the facilities of our customers who congratulate and appreciate our company.

What is ginning?

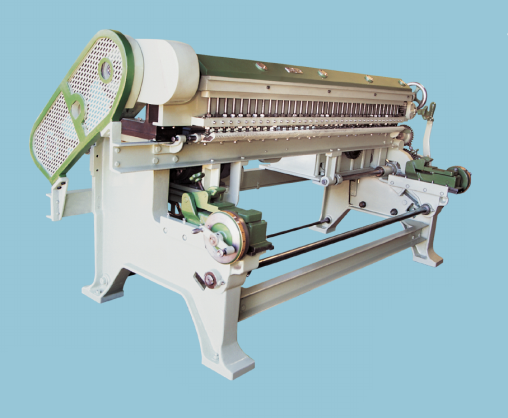

Separation of the core (cotton) cotton fiber from the core or ginning of the linter cotton over the core; This machine is called gin machine. There are three types of gin machines, collectively, with saws and hooks. In our country, there are gin machines which are collective and sawed.